AI Shifts the Paradigm of Aerospace Structural Modeling

Artificial intelligence (AI) can and should be a practical partner in changing the way aerospace structural modeling is accomplished, remarked Wenbin Yu. While physics-based models remain essential, AI can accelerate computation, fill knowledge gaps, integrate workflows, and make advanced simulation tools accessible to more engineers, he added, describing this new paradigm in detail during an AIAA Journal Keynote Seminar Series webinar.

Wenbin Yu, Milton Clauser Professor in the School of Aeronautics and Astronautics at Purdue University, presented this AIAA Journal Seminar Series webinar, “Shifting the Paradigm of Aerospace Structural Modeling with AI,” on 14 October 2025. Click here to view the webinar.

Yu, an AIAA Associate Fellow who has chaired the AIAA Materials Technical Committee, is the Milton Clauser Professor in the School of Aeronautics and Astronautics at Purdue University. He is also the director for the Composites Design and Manufacturing HUB and the chief technology officer of AnalySwift LLC.

In this must-see webinar for anyone interested in the future of aerospace structural modeling, Yu explains why using physics still makes sense for structural design. He described that Newton-like models are more explainable, extrapolatable, and predictive than AI models and produce the high-quality data needed to train trustworthy AI models.

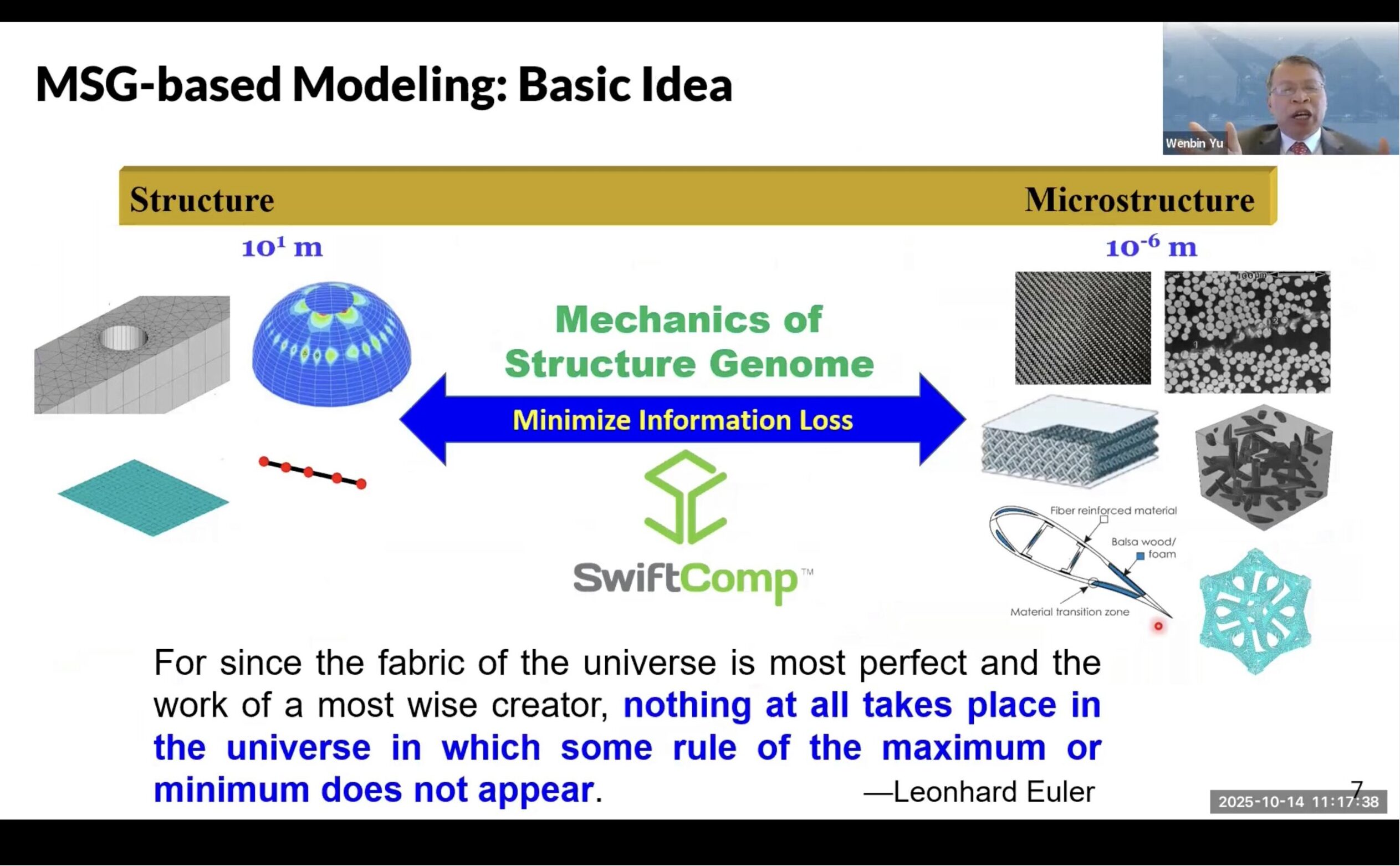

At the heart of Yu’s presentation is the Mechanics of the Structure Genome (MSG), a top-down multiscale modeling framework that flips the usual bottom-up, scale-separating workflow. Instead of homogenizing parameters to a material point or making ad hoc assumptions, MSG starts with the system-level model that is actually what is being worked on, i.e., a beam, plate, shell, or 3D body, then chooses a minimal “structure gene” – the smallest mathematical building block that captures the relevant physics – and maps material information into that reduced description. That mapping minimizes information loss so system behavior and important local effects are preserved even when dimensionality is reduced.

Further, Yu noted, MSG is versatile. It recovers classical models – for example, it can derive classical laminate theory without inconsistent plane-stress or Kirchhoff assumptions – and generalizes to sandwich panels, perforated panels, metamaterials, and more. Because the structure gene can be 1D, 2D, or 3D depending on symmetry and uniformity, MSG avoids needless computational expense. That clarity helps disentangle structural behavior from material behavior, a frequent source of confusion in metamaterials literature, Yu added.

A key benefit of MSG is that it unifies structural mechanics and micromechanics. “MSG enables you to retain existing structural designs while leveraging advances in new materials. It supplies appropriate constitutive models for anisotropic, heterogeneous materials and structures, which characterize most advanced aerospace materials,” Yu said.

This supports rigorous multi-mesh coupling and a mathematically consistent way to bridge disparate discretizations. MSG has also been used to build an efficient progressive damage analysis workflow that alternates homogenization and de-homogenization, yielding large speed increases over conventional damage simulations.

AI is pragmatic, Yu insisted. He identified four bottlenecks for physics-based modeling – computing, knowledge, integration, and accessibility – and describes in compelling detail how AI can help with each. Neural networks make extremely fast, accurate circuit-style surrogates when trained on good data; hybrid physics–ML (machine learning) approaches can discover unknown constitutive behavior or infer missing inputs from easily measured structural data; and large language models (LLMs) can orchestrate multi-tool workflows via natural language, democratizing access for non-specialists, he explained.

Yu offered concrete examples. Deep-learning surrogates reproduce hour-long multiscale simulations in fractions of a second for woven composite thermal conductivity, enabling design loops and uncertainty quantification that would be impractical otherwise.

The cornerstone of all this is Composites AI, an expert system Yu described that can ingest published models and scripts, answer natural-language questions, run integrated multiscale workflows, perform parametric studies or optimizations, and serve routine simulation requests without human intervention. This AI platform can streamline the design, simulation, and performance evaluation of composite structures such as rotor blades, shells, and panels.

Yu stressed complementary approaches – exhaust physics-based modeling first, use it to generate trustworthy data, then deploy AI where it adds value – to speed things up, fill missing knowledge, and make tools accessible.

Yu presented MSG plus AI as a pragmatic pathway to address current technical challenges while preserving physical rigor for structural modeling. His message: the future of aerospace structural modeling depends on these hybrid and complementary workflows, where physics-based models and AI not only co-exist, but actively augment one another. The result is this new paradigm that delivers both scientific rigor and practical power for design. Yu extolled the virtue of AI as a framework for modernizing aerospace structural modeling.

View all the AIAA Journal Series Seminar webinars featured in the Multimedia section

link