Design and application of a prefabricated structure for large-span arch open-cut highway tunnels

As China’s population ages and the demographic dividend diminishes, a significant reduction in the number of young and middle-aged laborers at construction sites has resulted in a sharp increase in labor costs, thereby increasing project costs1. Traditional construction methods are plagued by issues such as high labor intensity, extensive material consumption, high carbon emissions, minimal mechanization, inconsistent quality, slow construction speeds, and high vulnerability to natural conditions2. Consequently, an imperative transformation within the construction engineering industry is underway, compelling the comprehensive promotion of new urban construction, advancements in intelligent construction, the utilization of green building materials, and prefabricated construction to achieve the national policy goals ofdual carbon control.

The prefabricated structure demonstrates unique advantages in the construction field due to its notable characteristics of high efficiency, low carbon, and environmental friendliness3,4. Among them, the connection joints of prefabricated components are the core of the prefabricated structure, influencing not only the overall mechanical properties and load-bearing capacity of the structure5, but also being closely related to the manufacturing process of components, construction and assembly efficiency, as well as the waterproof and sealing performance of the structure. For the underground structure of prefabricated open-cut tunnels, this paper adopts the grouting tenon-and-groove joint to promote more efficient and precise rapid assembly of prefabricated structures6,7.

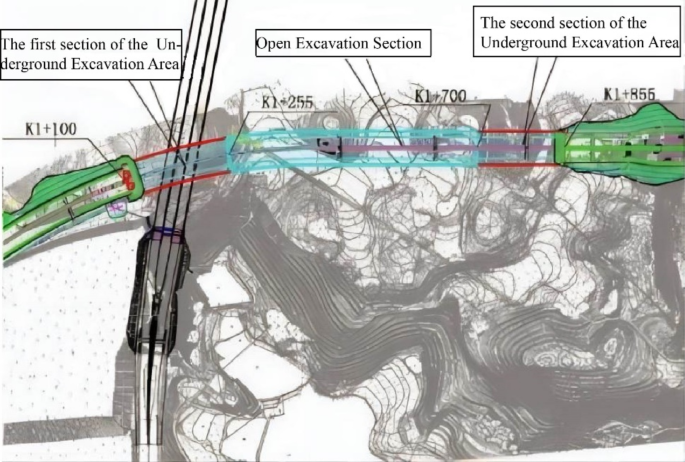

This paper takes Xinsen Avenue in Jinfeng Park of the Chongqing High-tech Zone as the background. The road is the main urban road in the north‒south direction of the park, with a total length of 2.5 km, including a double-arch eight-lane tunnel. The tunnel has a total length of 790 m, a net width of 16.5 m, and a net height of 5 m. The starting section crosses the third-stage tunnel of Gaoteng Avenue and connects with the reconstruction interchange of Gaolong Avenue after leaving the tunnel. The tunnel construction method combines underground excavation and open excavation: K1 + 065 ~ K1 + 255 is the first section of underground excavation, which is 190 m long K1 + 700 ~ K1 + 855 is the second section of underground excavation, which is 155 m long; and the remainder is the open-cut section, which is 445 m long. The section is designed with an assembled lining, and the filling thickness is 8.5–11.5 m, as shown in Fig. 1.

Plan layout of the Xinsen Avenue Tunnel in Chongqing.

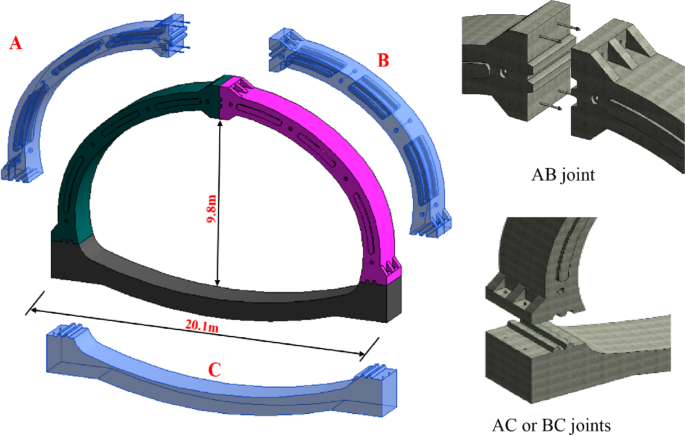

The standard ring of the prefabricated tunnel in the open-cut tunnel is divided into 2 m rings in the longitudinal direction, including 208 rings on the left and 209 rings on the right, for a total of 417 rings. As shown in Fig. 2, the lining structure adopts a design scheme combining partial prefabrication and cast-in-place methods. The inverted arch adopts the cast-in-place scheme (C block), the arch and the sidewall are composed of prefabricated components, the prefabricated part is divided into 2 blocks (A, B blocks), and the closed-cavity thin-walled prefabricated assembly structure type is adopted8,9,10 In the circumferential and longitudinal directions, the prefabricated components are connected by grouting mortise joints. The concave and convex tenon and mortise are set at the joint, and the joint is bridged by pouring the slurry into the joint gap to transfer the occlusal shear force and strengthen the bending resistance and anti-deformation ability to ensure the reliability of the structural force transmission.

Standard ring component diagram.

The open-cut prefabricated structure system is complex, and the structural system changes continuously during construction, significantly affecting the force-bearing, deformation, and stability of the structure. Several factors influence this, including (1) the interaction between joints and structure, strata and structure, and the foundation pit support structure and the prefabricated structure; (2) continuous changes in the structural system during construction, along with changes in backfill, hydrostatic pressure, and other load effects; and (3) changes in load effects during use, such as internal usage loads, earthquake effects, and civil defense load effects. Therefore, calculating and analyzing the overall effect of the structure under the influence of multiple factors is particularly important.

Currently, monitoring efforts for prefabricated structures, such as shield tunnels and underground utility corridors, primarily focus on comprehensive performance monitoring and in-depth analysis of overall structural behavior11,12,13. Regarding subway stations, Peng et al.14. conducted extensive research on the mechanical characteristics of prefabricated underground station structures during the backfilling stage. They established an incremental method structural calculation model to explore the effects of different conditions on the internal force distribution and stability of these structures. Additionally, Lin et al.15,16,17, using long-term field monitoring data from prefabricated stations in the Changchun subway, meticulously analyzed the performance and behavior changes of arch joints during various construction stages. Furthermore, Xiao et al.18 combined on-site monitoring with numerical simulation to systematically study the stress characteristics of prefabricated urban utility tunnels under different conditions, identifying potential risk areas and possible failure modes. Hak Joon Kim et al.19 by comparing field-measured data with numerical analysis results, conducted an in-depth analysis of the mechanical behavior of three-hinge prefabricated arch structures at different stages, emphasizing the influence of soil-structure interaction on structural performance. These studies provide valuable references and guidance for the design, construction, and operation of prefabricated underground structures.

Therefore, based on experimental research findings of prefabricated station structures in Changchun subway and integrating results from numerical theoretical analysis20,21,22, along with long-term on-site monitoring measurements, this study extensively discusses the trends of stress distribution, relative deformation, and relative rotation angle of tunnel joints over the construction process. It provides empirical data on the performance of prefabricated structures under actual loading conditions. This research not only validates the effectiveness and reliability of prefabricated assembly techniques in large-span underground structures but also offers essential technical references for similar project designs and constructions.

link